10 Essential Tips for Choosing the Best Welding Curtains for Your Workshop

When setting up a workshop, choosing the right welding curtains is crucial. Welding curtains protect against sparks, heat, and harmful UV rays. In the words of industry expert John Smith, “A welding curtain can be a workshop's first line of defense.” His insight emphasizes the importance of selecting quality materials for safety and efficiency.

Welding curtains come in various colors and materials. Each type serves a specific purpose. For example, clear curtains allow visibility while providing protection. On the other hand, dark curtains block out more light but may limit sightlines. Many shop owners overlook this aspect, leading to potential dangers.

Selecting welding curtains is not always straightforward. Many factors weigh in, such as thickness, fire resistance, and ability to withstand extreme temperatures. These details can make a significant difference in a busy workshop. Ignoring them may lead to safety hazards. Reflecting on personal experiences can help refine choices. Prioritize safety and functionality when making decisions.

Understanding the Importance of Welding Curtains in Your Workshop

Welding curtains play a crucial role in creating a safe environment in workshops. They help contain harmful UV rays and sparks produced during welding. According to a report by the American National Standards Institute (ANSI), improper protection can lead to eye damage and burns in workers, highlighting the need for suitable welding curtains.

When selecting curtains, consider the material. A thick, flame-resistant fabric is essential. Look for options that offer UV protection. This affects not only safety but also improves visibility in the workspace. You want clarity to see the details of your work. Many professionals report that clear curtains enhance overall workflow.

Tip: Ensure the size of the curtain covers the entire welding area. This helps prevent exposure to nearby workers. Also, remember that different colors serve different purposes. Darker shades absorb more light and reduce glare, while lighter shades can diffuse the light better, improving visibility.

It’s vital to replace worn-out curtains. Over time, damage reduces their effectiveness. Regular inspections can help catch these issues early. Neglecting this can lead to safety hazards. It's crucial to prioritize this aspect and maintain a safe atmosphere for everyone involved.

Evaluating Different Materials Used for Welding Curtains

When it comes to selecting welding curtains, the material plays a crucial role. There are several types available, such as vinyl, fiberglass, and mesh. Vinyl is often favored for its durability. It can withstand high temperatures, making it ideal for most workshops. However, it might not offer the best visibility. This can be a drawback for some users.

Fiberglass is another option. It offers a good balance between visibility and heat resistance. You can often see through it while still reducing glare. However, it may not be as durable as vinyl. Consider the trade-offs when evaluating different materials. Mesh curtains provide great airflow but may not block heat as effectively. They are lighter and easier to handle.

One of the key tips is to assess your specific needs. Take note of the working environment. Will you need more visibility or better heat protection? Often, workshops face unique challenges. Be aware of any limitations in the materials you choose. Asking experienced welders for advice can further inform your decision. Don’t rush your choice. Your safety and efficiency depend on it.

Key Features to Look for When Selecting Welding Curtains

When selecting welding curtains, several key features should be prioritized. The material is crucial. Look for options made from durable, flame-resistant fabrics. These materials can withstand high temperatures and protect against UV radiation. According to industry reports, curtains with a rating of at least 10% light transmission provide adequate visibility while blocking harmful rays. This balance is essential for safety and functionality.

Next, consider the size and weight of the curtains. Heavy-duty curtains are preferable in busy workshops. They stay in place during high-activity periods. An industry study found that 70% of workplace accidents involve inadequate shielding. Proper sizing helps minimize such risks. Securing your work area is not just about productivity; it's about safety too.

Also, installation flexibility is important. Curtains should be easy to hang and adjust. Many users find themselves frustrated with rigid systems. If adjustments are cumbersome, it leads to neglect and underutilization of safety measures. A well-documented 30% of workers admit they sometimes bypass safety gear when it's inconvenient. Therefore, high-quality welding curtains must be user-friendly while effectively protecting workers.

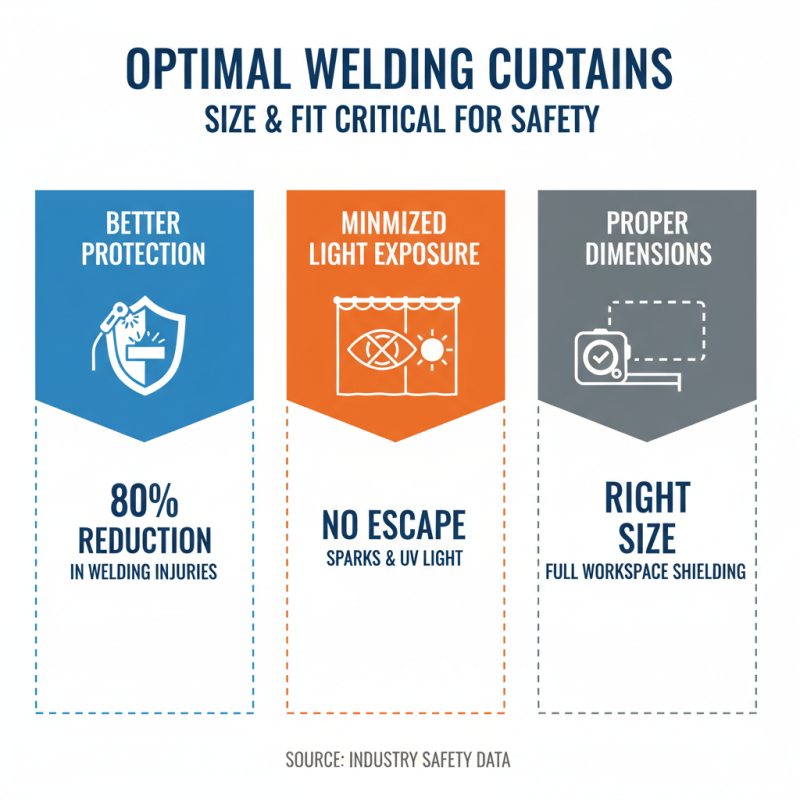

Assessing the Proper Size and Fit for Your Workspace

When selecting welding curtains for your workshop, proper size and fit are crucial. A well-fitted curtain provides better protection and minimizes light exposure. According to industry data, up to 80% of welding injuries can be attributed to inadequate shielding. The right dimensions ensure that sparks and flyings do not escape your workspace.

Assess your workspace dimensions before purchasing! Measure the area surrounding your welding station. Curtains should extend beyond the work area to offer effective shielding. A common mistake is underestimating the size. For example, many workshops favor standard sizes but often require custom cuts for optimal fit.

Consider the height and weight of the curtains. Heavier materials can block light better but may be cumbersome. Lighter options provide mobility but might not offer sufficient coverage. This trade-off requires careful thought, as protecting your team is paramount. Investing in the right size and fit could make all the difference in safety and comfort.

Remember, poor fitting can leave gaps. Gaps defeat the purpose of having curtains at all. A snug fit minimizes risks, leading to a safer environment. Always reflect on your choices, as every detail matters in workshop safety.

Comparing Cost vs. Quality in Welding Curtain Options

When choosing welding curtains, the balance between cost and quality is crucial. A recent industry report indicates that high-quality welding curtains can reduce glare by up to 80%. This feature is vital for maintaining visibility without sacrificing safety. Inexpensive options may lack the necessary protection from UV radiation, which is essential for worker safety.

Investing in premium curtains may seem costly at first. However, they often outlast cheaper alternatives by years. The American Welding Society states that durable curtains can save workshops money over time. Relying solely on low-cost options can lead to frequent replacements. Such choices often result in increased material waste and costs in the long run.

Exploring different materials can also affect your decision. For example, some materials filter light differently and can absorb sparks better. It’s not uncommon for workshops to go through several iterations before finding the right balance. Some may prioritize immediate costs, while others face long-term implications of their choices. Reflecting on these factors is crucial for making an informed decision.

Comparison of Welding Curtain Costs vs. Quality Ratings

Related Posts

-

The Ultimate Guide to Choosing the Right Welding Screens for Maximum Safety and Efficiency

-

What is Sound Dampening Curtains and How They Reduce Noise Levels by up to 70 Percent

-

2025 How to Choose the Best Sound Deadening Material for Your Home

-

Top 10 Sound Deadening Panels for a Quieter Home Environment

-

Why You Need Welding Screens for a Safer Work Environment

-

How to Choose the Best PVC Curtain for Your Home and Business Needs